ABS Advice

Find advice in the menu to your left about how to work with ABS plastic, including drilling, riveting, screwing, bolting, bonding and cleaning.

Please note that these guidance notes do not constitute a binding assurance of suitability for a particular end use. In view of the large number of factors which can influence the use of products, these notes do not relieve customers of the need to carry out their own tests and experiments.

Drilling

Drills should be sharp and ground with a “0”deg’ rake to prevent the ABS “corkscrewing” up the shank. Speeds for example of 3000 rpm for a 3mm drill and 900 rpm for a 12mm drill are recommended. If a drill requires lubrication, soapy water can be used. Compounds such as “Rocol” or other oils must not be used. Note that the minimum distance between any hole and the edge of the material, should be not less that the hole diameter.

Riveting

ABS can be riveted, but any compression of the material will set up stresses which over time can manifest themselves as cracks. If the material must be riveted, then it is advisable that low strength, large head, peel types are used, with additional washers spreading the load. Ideally a spacer/insert of HDPE/PP or Nylon, slightly thicker that the ABS, should be used. Rivet diameters should be at least equal to the total thickness of materials. Rivets should not be placed closer to an edge than about 5x their diameter. The hole in the ABS should maintain a clearance when the rivet is compressed.

Screwing/Bolting

As with riveting, holes in the ABS should be a clearance for a screw. Screws should be inserted with a washer to spread the load and should be tightened with a torque driver to achieve minimum compression and hence minimum stress. Ideally a spacer/insert of HDPE/PP/Nylon, slightly thicker that the ABS would be used, to prevent any compression of the ABS. If a screw requires lubrication to help insertion, soapy water can be used. Compounds such as “Rocol” or other oils must not be used.

Bonding

ABS bonds readily to itself and other materials. Surface preparation and the correct choice of adhesive are crucial to a successful bond. However solvent attack will weaken any plastic and propagate stress cracking, therefore it is important to select an adhesive which is free from chemicals unsuitable for ABS. Advice from adhesive manufacturers and material suppliers should be sought and tests carried out to evaluate the performance of adhesives.

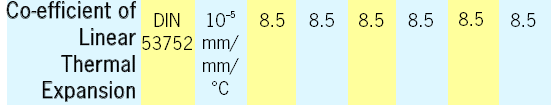

Thermal Expansion

Where a material is held with a different material (ie ABS & steel), the assembly should allow for the different thermal expansions to take place without compromising either material, for example by allowing enough clearance on assembly. Below is a typical value for guidance.

Cleaning

Use “Flash” or something similar in warm water, or undiluted, rinsed off with water. A stiff bristle brush can be used where dirt is engrained. In extreme cases Iso-Propyl-Alcohol can be used on stubborn marks, however it must be used sparingly and thoroughly rinsed with water.

Cleaning

Use “Flash” or something similar in warm water, or undiluted, rinsed off with water. A stiff bristle brush can be used where dirt is engrained. In extreme cases Iso-Propyl-Alcohol can be used on stubborn marks, however it must be used sparingly and thoroughly rinsed with water.

Chemicals

ABS is suitable for use with a wide range of chemicals, however other chemicals are suitable with only limited use and some are not at all suitable. Simple “stress & paint” tests are useful initial indicators of effect, but do not necessarily ensure satisfactory performance in service. Applications involving chemicals (including bonding & cleaning) where there is a possibility of stress-cracking must be evaluated.